TSMC taped out its first chip in a process making limited use of extreme ultraviolet lithography and will start risk production in April on a 5-nm node with full EUV.

Its N5 that will use EUV on up to 14 layers will be ready for risk production in April. EUV aims to lower costs by reducing the number of masks required for leading-edge designs.

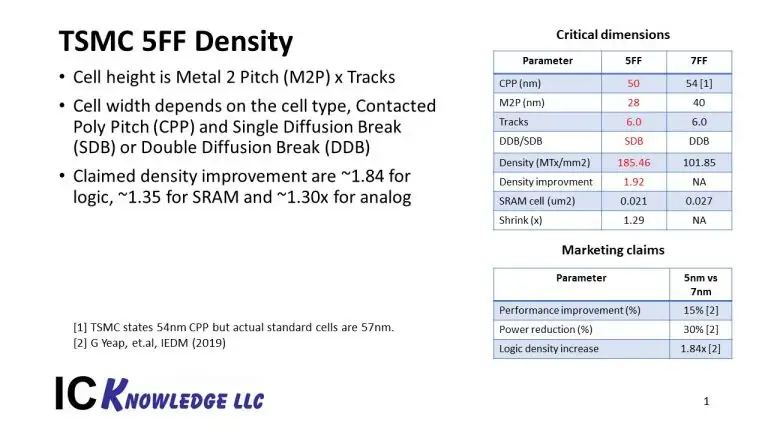

TSMC said that N5 will deliver 14.7% to 17.7% speed gains and 1.8 to 1.86 area shrinks based on tests with Arm A72 cores.

Chip designs for the N5 node can start today, although most EDA tools won’t hit a 0.9-version readiness until November. Many of TSMC’s foundation IP blocks are ready for N5, but some, including PCIe Gen 4 and USB 3.1, may not be ready until June.

https://www.eetimes.com/document.asp?doc_id=1333827&page_number=1One source pegged total costs for an N5 design including labor and licensing at $200 to $250 million, up from $150 million for a 7-nm chip today, limiting pursuit of Moore’s Law to the well-heeled.

EDIT: já não bebo mais nada hoje: "The N7+ node can deliver 6% to 12% less power and 20% better density; however, TSMC did not mention speed gains."

a não menção aos speed gains referem-se aos 7nm+ e não aos 5nm

a não menção aos speed gains referem-se aos 7nm+ e não aos 5nm

(acabei por apagar do quote para não criar confusão)

Seja como for, acho que o investimento da TSMC ascenderá aos 25$B, os preços para o desenvolvimento irão subir também, imagino que o preço das wafers também

Apesar de o PDK (process design kit) ainda estar na versão 0.9 e portanto ainda não finalizado, os EDA partners já anunciaram a disponibilização dos mesmos:

- Cadence

- Synopsis

- Mentor

Última edição:

foto de uma Mask do AMD Thoroughbred A numa wafer de 8" (200mm)

foto de uma Mask do AMD Thoroughbred A numa wafer de 8" (200mm)